Business Phone: 704-485-8300

Wayne’s Cell: 980-622-8435

Fax: 704-485-8137

12153 Griffin-Greene Blvd.

Stanfield, NC 28163

Engineering and Machining:

wayne@thomasmachineproducts.com

Accounting:

acctg@thomasmachineproducts.com

EDM Capabilities

EDM Machines

•

5 Makino Wire EDM Machines:

o

(2) U3

o

(1) U3 H.E.A.T.

o

(1) Duo 64

o

(1) Duo 43

•

3 EDM Drill Machines:

o

Belmont SY-2535

o

Mitsubishi ED-200M

o

SST FE3 CNC

•

Max Machining Dimensions:

15.6” x 16.6” x 17”

•

Complex Tapers

•

Small Lot

•

Production

•

Prototyping

•

Manufacturability Design

Advice

Business Phone: 704-485-8300

Wayne’s Cell: 980-622-8435

Fax: 704-485-8137

12153 Griffin-Greene Blvd.

Stanfield, NC 28163

Engineering and Machining:

wayne@thomasmachineproducts.com

Business and Accounting:

acctg@thomasmachineproducts.com

EDM Capabilities

•

Max Machining Dimensions: 15.6” x

16.6” x 17”

•

Complex Tapers

•

Small Lot

•

Production

•

Prototyping

•

Manufacturability Design Advice

EDM Machines

•

5 Makino Wire EDM Machines:

o

U3

o

U3 H.E.A.T.

o

Duo 64

o

Duo 43

o

SP-43

•

3 EDM Drill Machines:

o

Belmont SY-2535

o

Mitsubishi ED-200M

o

SST FE3 CNC

Electronic

Discharge

Machining

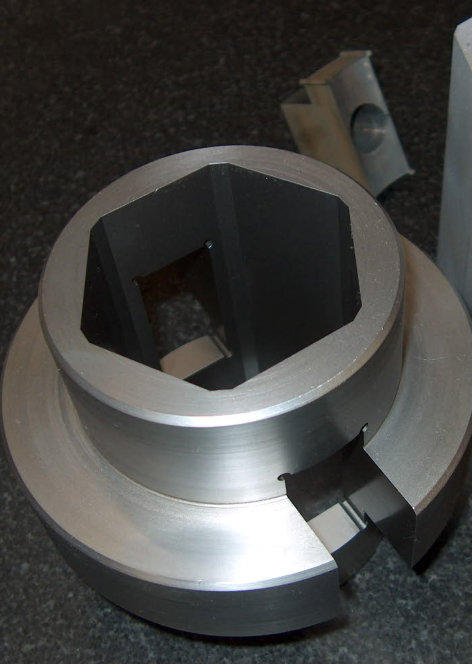

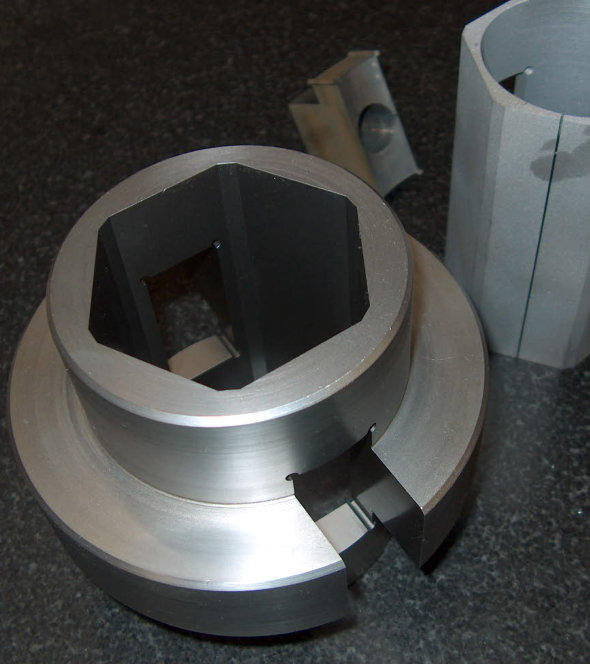

Thomas Machine does two types of electronic discharge machining: Wire EDM and EDM Drilling. Wire EDM is a non- traditional machining process that uses electrical discharges through a thin wire to erode conductive materials, regardless of hardness. EDM Drilling or Hole Pop EDM is used to burn small dimensionally accurate holes thorough nearly any depth conductive material. Thomas Machine has been providing these services since 2005 and has the experience to quickly and precisely produce your part features through Wire EDM.

EDM Capabilities

•

Max Machining Dimensions: 15.6” x 16.6” x 17”

•

Complex Tapers

•

Small Lot

•

Production

•

Prototyping

•

Manufacturability Design Advice

EDM Machines

•

5 Makino Wire EDM Machines:

o

(2) U3

o

(1) U3 H.E.A.T.

o

(1) Duo 64

o

(1) Duo 43

•

3 EDM Drill Machines:

o

Belmont SY-2535

o

Mitsubishi ED-200M

o

SST FE3 CNC

Business Phone: 704-485-8300

Wayne’s Cell: 980-622-8435

Fax: 704-485-8137

Engineering and Machining:

wayne@thomasmachineproducts.com

Accounting:

acctg@thomasmachineproducts.com

12153 Griffin-Greene Blvd.

Stanfield, NC 28163